Support our educational content for free when you purchase through links on our site. Learn more

Robot Control System Documentation: 15 Must-Know Essentials (2025) 🤖

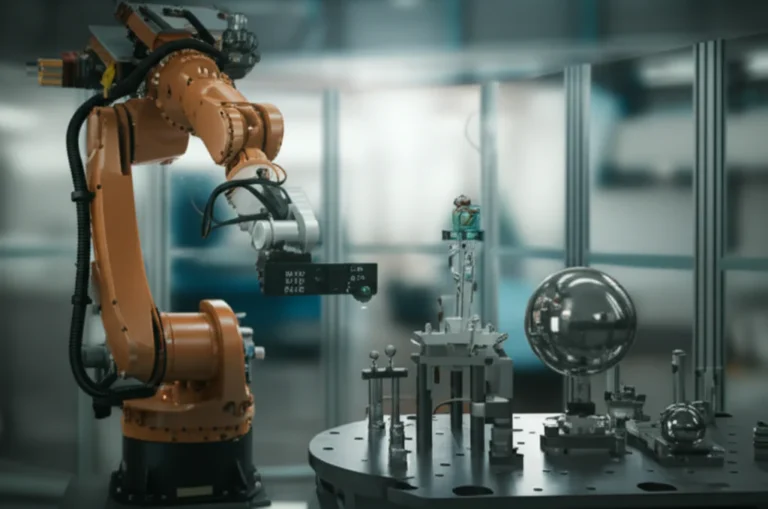

Imagine trying to operate a high-tech robot without a manual—no wiring diagrams, no software guides, no troubleshooting tips. Sounds like a nightmare, right? At Robot Instructions™, we’ve seen firsthand how stellar documentation transforms a frustrating robot build into a smooth, efficient, and safe operation. Whether you’re a robotics newbie or a seasoned engineer, understanding the ins and outs of robot control system documentation is your secret weapon for success.

In this comprehensive guide, we unravel the 15 essential types of documentation every robotics project needs—from hardware schematics and BOMs to software APIs and safety protocols. We’ll also share insider tips on crafting, maintaining, and future-proofing your docs with cutting-edge tools like AI and augmented reality. Curious about how to keep your documentation alive amid rapid iterations? Or how the REV Robotics Control Hub’s documentation stacks up? Stick around—we’ve got you covered.

Key Takeaways

- Robot control system documentation is vital for safety, efficiency, and maintainability.

- The documentation suite includes hardware specs, software guides, user manuals, maintenance procedures, and compliance documents.

- Version control and collaborative tools are game-changers for keeping docs accurate and up-to-date.

- Emerging tech like AI-generated docs and AR overlays will revolutionize how we interact with robot manuals.

- Planning your documentation strategy upfront saves time and headaches down the line.

Ready to master your robot’s brain and keep it running like clockwork? Let’s dive in!

Table of Contents

- ⚡️ Quick Tips & Essential Facts for Robot Control System Documentation

- 🕰️ The Unsung History of Robot Documentation: From Punch Cards to Digital Twins

- 🤖 Demystifying Robot Control System Documentation: What It Is & Why It’s Your Robot’s Brain

- 1. The Many Hats of Robot Docs: A Comprehensive Classification of Control System Documentation Types

- 1.1. The Nuts & Bolts: Hardware Documentation Essentials for Robotics

- 1.2. The Code & Logic: Software Documentation Deep Dive for Robot Control Systems

- 1.3. Empowering Operators: User Manuals & Operational Guides for Robot Systems

- 1.4. Keeping Robots Rolling: Maintenance & Troubleshooting Manuals

- 1.5. Safety First, Always: Compliance & Regulatory Documentation

- 🛠️ Building Better Bots, One Document at a Time: Our Expert Process for Crafting Superior Robot Documentation

- 2.1. The Blueprint Phase: Planning Your Documentation Strategy from Concept to Deployment

- 2.2. Your Digital Toolkit: Essential Documentation Software & Platforms We Swear By

- 2.3. The Golden Rules: Best Practices for Clarity, Consistency, and Control in Robot Documentation

- 2.4. Teamwork Makes the Robot Dream Work: Collaborative Documentation Strategies for Robotics Engineers

- 🚧 Navigating the Documentation Minefield: Common Challenges & Our Solutions

- 🚀 The Future is Now: AI, AR, and Interactive Robot Documentation

- Conclusion

- Recommended Links

- FAQ

- Reference Links

⚡️ Quick Tips & Essential Facts for Robot Control System Documentation

Welcome! We’re the engineers at Robot Instructions™, and we’ve seen it all: the good, the bad, and the “where-on-earth-is-the-manual?” ugly of robotics. Before we dive deep into the digital soul of your machine—its documentation—let’s get you up to speed with some hard-won wisdom. Think of this as the cheat sheet you wish you had before your first all-nighter with a new robot.

| Fact/Tip | Why It’s a Game-Changer | Our Expert Take |

|---|---|---|

| ✅ Version Control is Non-Negotiable | Prevents “v2_final_FINAL_thisone(3).docx” chaos. Tracks every single change. | Use Git. Seriously. It’s the industry standard for a reason. It saves projects, careers, and sanity. |

| ✅ Write for the End User | The person reading it might be a sleep-deprived technician at 3 AM, not the PhD who designed it. | Use clear, simple language. Add diagrams. A picture is worth a thousand lines of technical jargon. |

| ❌ Don’t Treat Documentation as an Afterthought | It leads to errors, downtime, and safety hazards. It’s as crucial as the code itself. | Document as you go! It’s easier to jot down notes while you’re in the zone than to try and remember why you used a specific resistor six months later. |

| ✅ A Good BOM is Gold | A detailed Bill of Materials (BOM) makes repairs and replication a breeze. | Include part numbers, suppliers, and even alternative components. Your future self (or colleague) will thank you. |

| ✅ Standardize Everything | Consistent templates, naming conventions, and style guides make documents predictable and easy to navigate. | Create a simple style guide for your team. It eliminates confusion and makes collaboration smoother. |

| ❌ Never Ignore Safety Docs | In robotics, this isn’t just red tape; it’s what prevents accidents and injuries. | Risk assessments and emergency procedures are the most important pages in your entire documentation suite. Period. |

🕰️ The Unsung History of Robot Documentation: From Punch Cards to Digital Twins

Let’s hop in the DeLorean for a moment. Back in the day, “robot documentation” was often a thick, coffee-stained binder filled with cryptic schematics and code printouts on green bar paper. If you were lucky, the engineer who wrote it was still at the company. If not? Good luck, pal. You were basically an industrial archaeologist.

We remember a project involving an old pick-and-place arm from the 80s. The documentation was a single, faded blueprint. We had to use magnifying glasses to decipher component values! It was a painful reminder of how far we’ve come. The evolution from those static, paper-based relics to today’s dynamic, interactive digital twins is nothing short of a revolution. This journey mirrors the evolution of robotics itself—from simple, pre-programmed machines to the complex, AI-driven systems we see in fields like Agricultural Robotics and beyond.

Today, the best documentation is a living, breathing entity. It’s version-controlled, collaborative, and accessible from a tablet on the factory floor. It might even use Augmented Reality to overlay instructions onto the robot itself. Wild, right? But this evolution didn’t happen overnight. It was driven by necessity, by costly mistakes, and by the relentless push for more efficient, safer, and smarter robots.

🤖 Demystifying Robot Control System Documentation: What It Is & Why It’s Your Robot’s Brain

So, what exactly is a robot control system documentation suite?

Think of it this way: if the robot’s hardware is its body, and the software is its consciousness, then the documentation is its memory and its instruction manual. It’s the complete, unabridged story of your robot—how it was built, how it thinks, how to operate it, and how to fix it when things go sideways.

It’s not just one document; it’s a whole library. It covers everything from the mechanical specifications of a component like the REV Robotics Control Hub to the high-level software architecture that governs its behavior. As the FIRST Tech Challenge documentation puts it, the Robot Controller “acts as the ‘brains’ of the robot,” and the documentation is the user guide to that brain.

💡 The Power of Precision: Why Stellar Documentation is Non-Negotiable

Ever tried to assemble IKEA furniture without the instructions? Now imagine that furniture is a six-axis industrial arm that costs more than your car and can move with incredible speed and force. See the problem?

Good documentation is the bedrock of successful robotics. Here’s why:

- ✅ Safety & Compliance: It ensures the robot is operated within safe parameters, protecting both people and equipment.

- ✅ Efficiency & Uptime: When a robot goes down, clear troubleshooting guides can mean the difference between minutes and days of lost productivity.

- ✅ Scalability & Maintenance: It allows new team members to get up to speed quickly and enables others to repair, replicate, or build upon your work.

- ✅ Consistency: It guarantees that procedures are followed correctly every single time, which is critical for quality control in manufacturing.

Without it, you’re not engineering; you’re just guessing. And in the world of robotics, guessing is expensive and dangerous.

1. The Many Hats of Robot Docs: A Comprehensive Classification of Control System Documentation Types

Robot documentation isn’t a monolith. It’s a collection of specialized documents, each with a unique purpose. Let’s break down the essential types you’ll encounter.

1.1. The Nuts & Bolts: Hardware Documentation Essentials for Robotics

This is where the physical world meets the digital. Hardware docs tell you everything about the robot’s body.

1.1.1. Schematics & Wiring Diagrams

The holy grail for any electrical issue. A good schematic is a roadmap of the robot’s nervous system. It shows how every component, from the main controller like a REV Control Hub to the tiniest sensor, is connected. It should be detailed, clearly labeled, and 100% accurate.

1.1.2. Bill of Materials (BOM) & Component Specifications

The BOM is your robot’s shopping list. It details every single part: motors, sensors, screws, wires, and controllers. A great BOM includes:

- Part numbers (e.g., for a specific servo or sensor).

- Manufacturer names (e.g., REV Robotics, AndyMark).

- Quantities.

- Links to supplier websites.

Component specification sheets, like the one for the REV Control Hub, provide critical details like voltage ranges and current limits. The documentation wisely warns, “DO NOT exceed the absolute maximum electrical specifications. Doing so will cause permanent damage…and will void the warranty.” Words to live by!

1.1.3. Assembly & Disassembly Guides

These are the step-by-step instructions for putting your robot together and taking it apart. They should be rich with visuals—CAD drawings, photos, or even videos. Think LEGO instructions, but for much cooler (and more complex) toys.

1.1.4. Calibration Procedures

Many components, especially sensors and robotic arms, need to be calibrated to function accurately. This documentation provides the precise steps to do so, ensuring your robot knows exactly where its limbs are in space and can interpret sensor data correctly.

1.2. The Code & Logic: Software Documentation Deep Dive for Robot Control Systems

If hardware is the body, software is the soul. This documentation explains the logic that drives the robot’s actions, a key component of Artificial Intelligence in modern systems.

1.2.1. Code Comments & Inline Documentation

Good code documents itself. Clear variable names, well-structured functions, and insightful comments are the first line of defense against confusion. Explain the why, not just the what. Why was this algorithm chosen? What edge case does this if statement handle?

1.2.2. API Documentation & Libraries

If your robot control system provides an Application Programming Interface (API) for others to use, this documentation is critical. It explains the available functions, their parameters, and what they return. Think of it as the user manual for your code.

1.2.3. Software Architecture & Design Documents

This is the high-level blueprint of your software. It shows how different modules interact, the flow of data through the system, and the overall design philosophy. It helps new developers understand the big picture before diving into the nitty-gritty code.

1.2.4. Configuration & Deployment Guides

How do you get the code from a developer’s laptop onto the robot’s controller? This guide explains it all: setting up the development environment, compiling the code, and deploying it to the hardware. For systems like the FTC Control System, this involves tools like the Blocks Programming Tool or Android Studio.

The video tutorial we’ve included gives a great real-world example of this. It walks you through crucial configuration steps like updating IP addresses in multiple files (main.py, api.py) and ensuring the correct WiFi credentials are in the .ino file for the robot’s ESP modules. As the narrator in our featured video points out, “that’s our local address on the network. We’re going to need this.” This highlights how a seemingly small configuration detail is absolutely essential for the whole system to work.

1.3. Empowering Operators: User Manuals & Operational Guides for Robot Systems

This is documentation for the people who will be interacting with the robot every day. It needs to be clear, concise, and focused on tasks.

1.3.1. Quick Start Guides & Tutorials

The goal here is to get a new user from unboxing to basic operation as quickly and painlessly as possible. The “Getting Started” section of the REV Robotics documentation is a perfect example, guiding users from unboxing to creating their first configuration file.

1.3.2. Operational Procedures & Workflows

This details the standard operating procedures (SOPs) for using the robot to perform its intended tasks. For a competition robot, this might involve explaining how to select an autonomous program (an “OpMode” in FTC terms) before a match begins.

1.3.3. Human-Robot Interaction (HRI) Guidelines

For collaborative robots (“cobots”) designed to work alongside humans, this is vital. It explains how to interact with the robot safely, what its indicator lights mean, and how to use its teaching pendant or interface.

1.4. Keeping Robots Rolling: Maintenance & Troubleshooting Manuals

Robots, like any complex machine, require maintenance and will occasionally break. This documentation is the key to minimizing downtime.

1.4.1. Preventative Maintenance Schedules

An ounce of prevention is worth a pound of cure. This schedule outlines routine checks and maintenance tasks—like lubricating joints, checking belt tension, or cleaning sensors—to keep the robot in peak condition.

1.4.2. Diagnostic Procedures & Error Codes

When an error light flashes, this is the document you grab. It should contain a comprehensive list of error codes, what they mean, and the step-by-step procedures to diagnose the root cause of the problem.

1.4.3. Repair & Replacement Instructions

This is the hands-on guide to fixing the robot. It should provide clear, detailed instructions for replacing common components like motors, sensors, or controllers, often referencing the assembly guides and BOM.

1.5. Safety First, Always: Compliance & Regulatory Documentation

This isn’t the most glamorous part of robotics, but it is arguably the most important.

1.5.1. Safety Protocols & Emergency Procedures

This section must clearly outline all safety protocols, including the location and function of all emergency stops (E-stops), lockout-tagout procedures, and what to do in case of an unexpected robot movement or other emergency.

1.5.2. Industry Standards & Certifications (e.g., ISO, ANSI/RIA)

For commercial and industrial robots, documentation must show compliance with relevant safety standards from organizations like the International Organization for Standardization (ISO) or the Robotic Industries Association (RIA). This is crucial for legal and insurance purposes.

1.5.3. Risk Assessments & Mitigation Strategies

This document identifies all potential hazards associated with the robot and details the strategies implemented to mitigate those risks. It’s a foundational document for ensuring a safe human-robot work environment.

🛠️ Building Better Bots, One Document at a Time: Our Expert Process for Crafting Superior Robot Documentation

Okay, so you’re convinced. You need great documentation. But where do you start? At Robot Instructions™, we’ve refined our process over countless projects. Here’s our secret sauce.

2.1. The Blueprint Phase: Planning Your Documentation Strategy from Concept to Deployment

You wouldn’t build a robot without a plan, right? The same goes for its documentation. Before you write a single word, ask these questions:

- Who is the audience? (Technicians, software developers, operators, safety inspectors?)

- What information do they need? (High-level overview, detailed code examples, step-by-step repair guides?)

- What format is best? (A wiki, a PDF manual, a series of video tutorials?)

- How will it be maintained and updated? (Who is responsible? What’s the process?)

Planning this upfront saves a massive amount of rework later.

2.2. Your Digital Toolkit: Essential Documentation Software & Platforms We Swear By

The right tools make all the difference. Forget generic word processors. For professional-grade documentation, you need specialized software.

| Tool Category | Examples | Why We Love It |

|---|---|---|

| Version Control | Git, Subversion (SVN) | Tracks every change, allows for collaboration, and provides a historical record. Essential for both code and docs. |

| Technical Writing | Confluence, Read the Docs, MadCap Flare | Built for creating structured, searchable, and maintainable documentation. Great for collaborative editing. |

| Diagramming & CAD | Lucidchart, draw.io, SolidWorks, Autodesk AutoCAD | For creating everything from software flowcharts to detailed mechanical drawings and wiring diagrams. |

👉 Shop for Top-Tier Software on:

- SolidWorks: Amazon | SolidWorks Official Website

- Autodesk AutoCAD: Amazon | Autodesk Official Website

2.3. The Golden Rules: Best Practices for Clarity, Consistency, and Control in Robot Documentation

These are the core principles we follow to create documentation that people actually want to use.

2.3.1. Time Travel for Docs: Mastering Version Control Systems for Robotics

We mentioned it before, but it bears repeating: use a version control system (VCS) like Git for your documentation. Just like with software, your documentation will evolve. A VCS allows you to track changes, revert to previous versions if you make a mistake, and allow multiple people to work on the same documents without overwriting each other’s work. It’s a lifesaver for managing the documentation of complex Autonomous Robots.

2.3.2. Standardized Templates & Style Guides

Create templates for common document types (e.g., maintenance logs, component specs). This ensures consistency and saves time. A simple style guide that defines terminology, formatting, and tone of voice will make your documentation suite feel cohesive and professional.

2.3.3. Visual Aids: Diagrams, Videos, and Interactive Content

Don’t just tell—show. Use:

- Screenshots for software guides.

- Flowcharts to explain processes.

- Photos and CAD drawings for hardware assembly.

- Video tutorials for complex procedures.

A short video can often explain a physical task far better than pages of text.

2.3.4. User-Centric Design: Writing for Your Audience

Always write with the end user in mind. Avoid jargon where possible, and explain it when it’s necessary. Organize information logically. Start with an overview, then provide details. Use headings, bullet points, and bold text to make the document scannable.

2.4. Teamwork Makes the Robot Dream Work: Collaborative Documentation Strategies for Robotics Engineers

Documentation should not be a solo effort. The best results come from collaboration:

- Mechanical engineers should write the assembly guides.

- Electrical engineers should create and verify the schematics.

- Software engineers should document the code and APIs.

- Technicians and operators should review the user manuals and provide feedback.

Using a centralized, wiki-based platform like Confluence can make this collaboration seamless.

🚧 Navigating the Documentation Minefield: Common Challenges & Our Solutions

Let’s be real: if creating great documentation were easy, everyone would do it. Here are the common traps and how we, as seasoned engineers, navigate them.

The “Too Busy to Document” Dilemma

This is the number one excuse. The project deadline is looming, and documentation feels like a “nice-to-have” that can be pushed off. This is a trap!

Our Solution: Make documentation part of the workflow. Don’t allow a task to be marked “complete” until its corresponding documentation is also complete. It might feel slower initially, but it saves an exponential amount of time in the long run during testing, handoff, and maintenance.

Keeping Up with Rapid Iteration

In agile robotics development, hardware and software can change daily. How do you keep the docs from becoming instantly obsolete?

Our Solution: This is another area where a VCS like Git is your best friend. Tie documentation updates to your code commits or hardware revisions. When a developer pushes a change to the robot’s control algorithm, the pull request should also include the updated documentation for that algorithm. This creates a “single source of truth” that evolves with the project.

Bridging the Gap: Hardware vs. Software Documentation

Often, the hardware and software teams work in silos, and their documentation reflects that. The result is a disjointed mess where it’s unclear how a software function corresponds to a physical action.

Our Solution: A unified documentation system and cross-functional reviews. The software team should be able to easily reference the hardware schematics, and the hardware team should understand the software architecture. We hold regular “doc reviews” where engineers from different disciplines read each other’s work to spot gaps and inconsistencies.

🚀 The Future is Now: AI, AR, and Interactive Robot Documentation

The future of robot control system documentation is incredibly exciting and is being heavily influenced by advances in Machine Learning. Static PDFs are on their way out. Here’s a glimpse of what’s next.

AI-Powered Documentation Generation & Search

Imagine AI tools that can automatically generate baseline documentation by analyzing your code, or intelligent search functions that understand natural language queries. Instead of searching for “motor error code 52,” a technician could ask, “What does it mean when the main drive motor is flashing red?” This is no longer science fiction; it’s on the horizon.

Augmented Reality (AR) for On-Site Maintenance & Training

Why read a manual when you can see the instructions? With AR glasses or a tablet, a technician could look at a robot, and the documentation would be overlaid directly onto their view. It could highlight the exact screw to turn, show a 3D animation of how to replace a part, or display real-time sensor data. This technology will revolutionize maintenance and repair, making it faster and less error-prone. It’s already being explored in Robotic Applications in Entertainment for complex stage machinery.

Digital Twins & Real-time Documentation

A “digital twin” is a virtual model of a physical robot that is updated in real-time with data from the actual machine. This creates the ultimate form of documentation: a living, breathing model that reflects the exact state of the robot at any given moment. You can use it to simulate changes before deploying them, troubleshoot issues remotely, and analyze performance data. It’s the pinnacle of a well-documented system, where the documentation is the system.

Conclusion

After our deep dive into the world of robot control system documentation, one thing is crystal clear: documentation is not just paperwork—it’s the lifeblood of your robot’s success. Whether you’re working with the versatile REV Robotics Control Hub or developing your own custom system, the quality and comprehensiveness of your documentation can make or break your project.

From our experience at Robot Instructions™, the REV Robotics Control Hub stands out as an affordable, robust, and well-supported platform with excellent documentation that covers hardware specs, software programming, and integration guides. Its modular ecosystem, including the Expansion Hub and Driver Hub, is well-documented and designed to scale with your needs. However, like any product, it’s not perfect—some users find the initial learning curve steep, especially when juggling multiple hubs and software tools simultaneously. But with the rich documentation and active community support, these challenges are easily overcome.

Remember the question we teased earlier: How do you keep documentation alive and useful in a fast-paced robotics environment? The answer lies in integrating documentation into your workflow, leveraging version control, and embracing collaborative tools. And as we look to the future, technologies like AI-assisted documentation and augmented reality promise to make robot manuals more interactive, intuitive, and indispensable.

So, whether you’re a FIRST Tech Challenge team, an industrial robotics engineer, or a hobbyist tinkering in your garage, invest in your documentation as much as you invest in your robot. It’s the best insurance policy against downtime, confusion, and costly mistakes—and the key to unlocking your robot’s full potential.

Recommended Links

Ready to level up your robot control system documentation and hardware? Check out these top picks:

- REV Robotics Control Hub & Accessories:

- Technical Writing & Version Control Tools:

- CAD & Diagramming Software:

- Books on Robotics Documentation & Engineering:

- The Art of Agile Development by James Shore & Shane Warden — Amazon Link

- Robot Operating System (ROS) for Absolute Beginners by Lentin Joseph — Amazon Link

- The Robotics Primer by Maja J Mataric — Amazon Link

FAQ

What are the key components of robot control system documentation?

Robot control system documentation typically includes hardware documentation (schematics, BOMs, assembly guides), software documentation (code comments, API references, architecture designs), user manuals (operational procedures, quick start guides), maintenance and troubleshooting manuals, and safety and compliance documents. Each component serves a distinct purpose, ensuring that engineers, operators, and technicians have the information they need to build, operate, and maintain the robot safely and effectively.

How do you create effective documentation for a robot control system?

Effective documentation starts with planning: identifying your audience, defining the scope, and choosing the right formats. Use version control systems like Git to track changes and collaborate. Employ standardized templates and style guides to maintain consistency. Incorporate visual aids such as diagrams and videos to enhance understanding. Most importantly, write with clarity and user-centric focus, avoiding jargon where possible and explaining necessary technical terms.

What software tools are used for documenting robot control systems?

Popular tools include version control systems like Git, technical writing platforms such as Confluence and Read the Docs, and diagramming/CAD software like SolidWorks, AutoCAD, and Lucidchart. These tools facilitate collaboration, maintainability, and clarity in documentation.

Why is documentation important in robot control system development?

Documentation is crucial because it ensures safety, efficiency, maintainability, and knowledge transfer. It helps prevent costly errors, reduces downtime by enabling faster troubleshooting, and allows new team members to onboard quickly. In regulated industries, documentation is also essential for compliance with safety and quality standards.

How can robot control system documentation improve maintenance and troubleshooting?

Comprehensive maintenance schedules and troubleshooting guides enable technicians to quickly identify and resolve issues, minimizing downtime. Detailed error code explanations and diagnostic procedures empower users to perform repairs confidently. Additionally, clear assembly and disassembly instructions reduce the risk of damage during maintenance.

What standards should be followed when documenting robot control systems?

Documentation should adhere to industry standards such as ISO 10218 for industrial robots and ANSI/RIA R15.06 for robot safety. Following these ensures compliance with legal and safety requirements. Additionally, adopting internal standards like consistent formatting, terminology, and version control best practices improves clarity and usability.

How does robot control system documentation support robot programming and operation?

Documentation provides programmers with API references, code examples, and architecture overviews that facilitate software development and debugging. For operators, manuals and quick start guides explain how to safely and effectively control the robot, select operational modes (like FTC’s OpModes), and perform routine tasks, ensuring smooth day-to-day operation.

Reference Links

- REV Robotics Official Website

- REV Robotics Control Hub Documentation

- FIRST Tech Challenge Control System Overview

- International Organization for Standardization (ISO)

- Robotic Industries Association (RIA)

- Git Version Control

- Atlassian Confluence

- SolidWorks CAD Software

- Autodesk AutoCAD

If you want to explore more about robot control systems and their documentation, check out our full Robot Instructions™ library. Happy building! 🤖✨